- What telescope mirrors are made of

- How we keep these giant mirrors in tip-top shape

- The unexpected obstacles in cleaning the largest telescope mirror in the world

Anyone who has ever cleaned windows or bathroom mirrors knows how quickly they collect dust and dirt. So how does the European Southern Observatory (ESO) keep the giant mirrors of its telescopes clean and shiny — in the middle of a desert?

Big, but perfectly smooth. Sturdy, but not too heavy. A telescope mirror in a state-of-the-art observatory needs to be a lot of things. To look deep into the cosmos, optical telescopes have to catch as much light as possible. For that, they need big mirrors. Very big mirrors. On top of that, ESO’s telescopes are housed in the Atacama Desert in Chile. With its thin, dry atmosphere and dark night sky, the desert offers ideal conditions for observing the Universe. But it also means that the telescope mirrors have to withstand temperature variations, without getting deformed. And that the dust of the desert is bound to make them dirty.

What are telescope mirrors made of?

It will not surprise you that the mirrors of professional telescopes are not made from ordinary glass. There are different materials used to cast these mirrors, and one of them is a special type of glass ceramic called Zerodur®. This material doesn’t really deform, even under harsh conditions and changing temperatures. Equally importantly, too, it can be ground and polished to perfection without cracking.

A telescope mirror has one job: to efficiently reflect the light it collects. To guarantee superb reflectivity, any imperfections on the mirror’s surface have to be smaller than the wavelength of the light the mirror collects, otherwise the signals from space get scattered around randomly. Optical telescope mirrors need to be super smooth because they observe short wavelengths, such as visible light.

To make them as reflecting as possible, the mirror blanks are first polished to perfection. But it doesn’t stop there, because the polished blanks are still partly transparent. That is why they get coated with a very thin, highly reflective layer of aluminium or silver — 10 000 times thinner than a human hair. Why so thin, you ask? A slightly thicker layer would also be rougher and therefore less reflective.

But even superbly crafted mirrors will degrade at some point. Unlike the mirrors you have at home, where the reflective layer is behind the glass, in telescope mirrors the reflective material is in front of it. The mirror coating has a limited life span, as silver and aluminium slowly become oxidised when they are exposed to the air. Luckily, the desert air is very dry, which makes the degradation process slower than in other places on Earth. But other dangers are lurking…

Dust before the dawn

A good motto for telescopes is ‘prepare and prevent instead of repair and repent’. Before even thinking about replacing the delicate reflective coating of the mirrors, our priority is to keep the desert dust away from them — as much as possible. Each of ESO’s optical telescopes is therefore housed in an enclosure that protects it from the harsh desert conditions. At night, the enclosure opens, observations start and the mirrors are exposed to the elements. Inevitably, dust accumulates on the mirror’s surface, absorbing and diffusing some of the light that should be focused on the telescope’s instruments. That means it’s time for some serious dust busting!

Who you gonna call? Dustbusters!

For most telescopes, cleaning is done by inclining the mirrors and spraying them with CO₂. At almost minus 80 degrees Celsius, the frozen CO₂ flakes cause tiny "explosions" when they land on the mirror, which is at room temperature. When the snowflakes explode, they lift up the dust from the surface, which floats away, leaving the mirror surface squeaky clean. During cleaning, the staff wears special suits so that no hair or lint lands on the mirror.

But regularly blowing away the dust from the mirrors is not enough to keep them in tip-top shape. The reflectivity of each mirror is strictly monitored, and when it deteriorates too much, the mirror will receive a new coating.

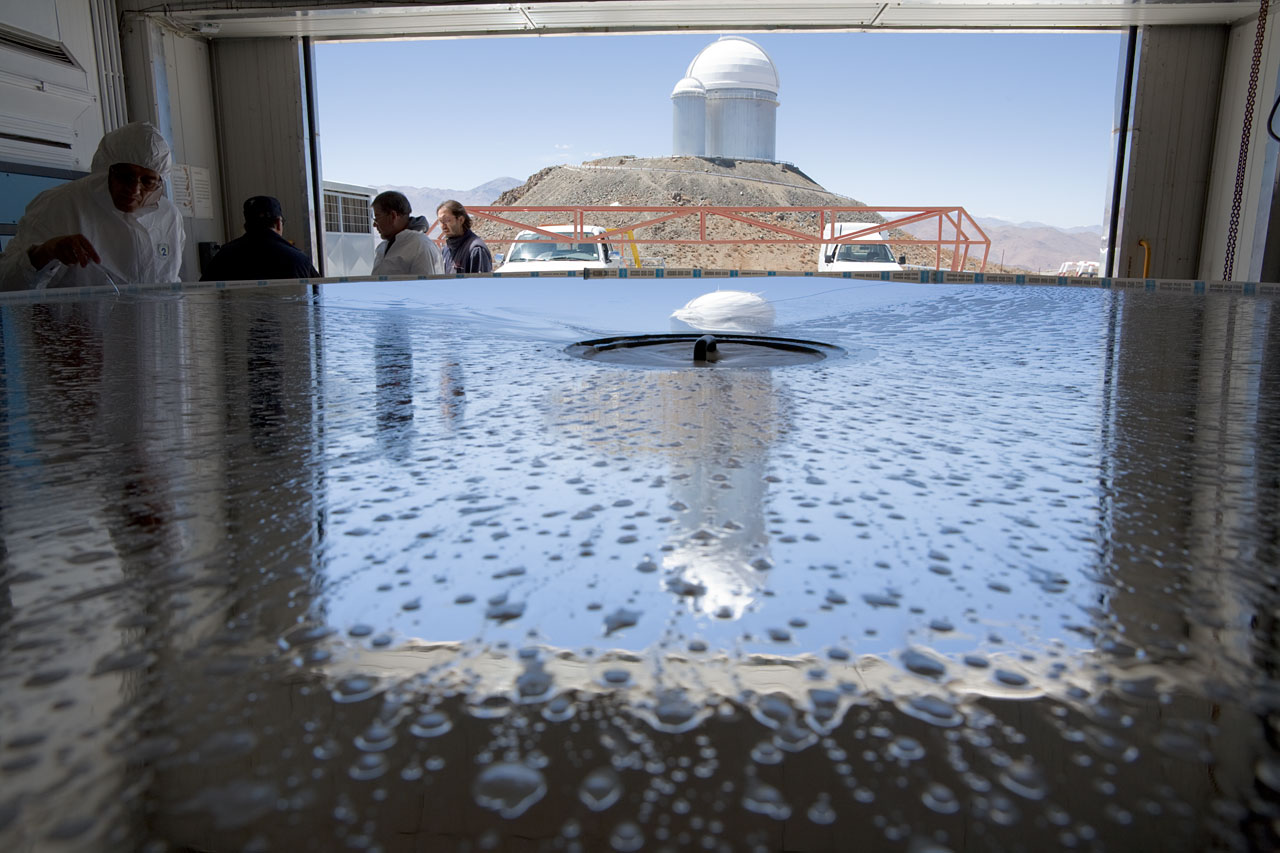

A sponge bath for the NTT

Located at La Silla Observatory in Chile, ESO’s New Technology Telescope (NTT) is a golden oldie. It saw its first light in March 1989. Its main mirror is relatively small, for ESO standards, with a diameter of ‘only’ 3.58 m, less than half the size of those of our Very Large Telescope (VLT).

On top of its weekly clean with CO₂ snow, the NTT receives a sponge bath every six months. For that, the mirror is removed from the telescope.

The NTT’s main mirror is washed by hand to remove the dirt accumulated on its surface. Armed with soft natural sponges, delicate soap and distilled water, ESO staff give the telescope mirror a good cleaning.

A tailor-made dishwasher for the VLT

But regularly cleaning dust isn’t enough. Eventually the coating itself loses some of its reflectivity and needs to be replaced with a fresh one. In the case of the VLT, the 8 m wide primary mirrors weigh 23 tonnes, making this a very delicate operation. There is no replacement mirror if it goes wrong!

The entire coating process takes about eight days. A special crane takes the entire mirror cell, weighing 45 tonnes, off the telescope and moves it onto a platform, which slides it out of the building. A truck then takes the carefully wrapped mirror to the recoating facility, located a few kilometers away.

There, bolt by bolt, engineers remove the mastodon mirror from its supporting cell. From then on, the mirror is no longer supported by the sophisticated anti-seismic devices in the cell, making it more vulnerable to earthquakes. The recoating process is therefore done as fast as possible.

Before being lowered onto a special moving bed, the underside of the mirror gets cleaned by hand to remove contaminants that could damage it in the next steps. It is then moved to the cleanroom, where a second round of manual cleaning is performed on the reflective side of the mirror. Then, finally, it’s washing time.

A dishwasher-like instrument removes the old aluminium coating with a chemical washing, until the original glass-ceramic material becomes visible again.

After its bath, aluminium particles are vapourised on the stripped mirror surface for a shiny new coating. The entire surface is covered using only 12 grams of aluminium, building a layer about 200 times thinner than the aluminium foil in your kitchen. After inspection, the rejuvenated mirror travels back home to the VLT, where it resumes its work for another 18 months.

ESO’s Extremely Large Telescope: a literal puzzle

Unlike the VLT and the NTT, which have mirrors made of one big piece of glass, the main mirror of ESO’s Extremely Large Telescope (ELT) will consist of 798 mirror segments. Aligned together in an intricate structure, they work together as one mirror with a 39 metre diameter.

So, how do we make sure that the 798 mirror segments of the ELT remain smooth and reflective? The solution is wonderfully simple – well, sort of. Every day, two segments will be taken out and replaced by freshly coated ones. Once removed, the mirror segments are taken through the cleaning and recoating process. The segments are coated with silver, with extra layers of nickel chromium and silicon nitride to protect the silver from tarnishing and improve how it sticks to the blank. The freshly coated segments are then stored away, to be put back in the mirror sometime later. In about two years, all segments will have been recoated and replaced. The mirror won't have gaps throughout this process, though, as we have replacement segments for this.

The art of cleaning 2.0.

Now that you master the basics of mirror cleaning and coating, you probably appreciate how many seemingly trivial details engineers need to think of when they devise an advanced ground-based observatory like the ELT. And the engineering doesn’t stop when a telescope sees its first light. Both in Chile, where the telescopes are hosted, and at the ESO Headquarters in Germany, engineers will continue to investigate the best ways to keep the telescope mirrors in tip-top shape. So who knows how we will be cleaning our telescope mirrors in 2040 and beyond?

Biography Hanna Huysegoms

After nine years of professionally talking and writing about books, Hanna wanted to dip her toe in other waters. The ESO telescopes piqued her curiosity, bringing back memories of her 10-year-old self, buried with her nose in astronomy books. As it turns out, the leap from writing about medieval manuscripts to writing about stars and exoplanets is not that big. Born and raised in Belgium, Hanna studied English and is passionate about accessible and easy-to-understand language in all domains.