Press Release

First segments of the world's largest telescope mirror shipped to Chile

18 December 2023

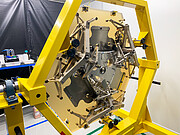

The construction of the European Southern Observatory’s Extremely Large Telescope (ESO's ELT) has reached an important milestone with the delivery to ESO and shipment to Chile of the first 18 segments of the telescope’s main mirror (M1). Once they arrive in Chile, the segments will be transported to the ELT Technical Facility, at ESO’s Paranal Observatory in the country’s Atacama Desert, where they will be coated in preparation for their future installation on the telescope main structure. Unable to be physically made in one piece, M1 will consist of 798 individual segments arranged in a large hexagonal pattern, with an additional 133 being produced to facilitate the recoating of segments. With a diameter of more than 39 metres, it will be the largest telescope mirror in the world.

The final stage in the production process of M1 segments — polishing — was carried out by world-leading optical systems manufacturer Safran Reosc near Poitiers, central France, at a building completely refurbished to work on this delicate task. As part of the process, Safran Reosc developed new automation workflows and measurement techniques to ensure that the polishing met the high standards required for ESO's ELT. The surface irregularities of the mirror are less than 10 nanometres (less than one thousandth of the width of a human hair). To reach this level of performance, Safran Reosc used a technique called ion-beam figuring, in which a beam of ions sweeps the mirror surface and removes irregularities atom by atom.

While only 18 segments have been shipped thus far, many more will soon be delivered by Safran Reosc to ESO. On 1 November 2023, the 100th segment went out of the production line and entered into the extensive inspection phase that takes place before final delivery. Furthermore, Safran Reosc has achieved a production rate in excess of four segments per week, with a target of five a week expected soon, a remarkable achievement for the series production of incredibly high-accuracy optics.

The construction of ESO’s ELT has required the close involvement of multiple companies in Europe and Chile with ESO’s teams, highlighting how the telescope is a true international endeavour. The mirror segments were cast by the German company SCHOTT at their facility in Mainz, Germany, before being delivered to Safran Reosc in France for polishing. Other companies involved in the work done on the segment assemblies include: Dutch company VDL ETG Projects BV who produced the delicate segment supports, German-French FAMES consortium who developed and manufactured the 4500 nanometric-accuracy sensors monitoring the relative position of each segment, and German company Physik Instrumente who designed and manufactured the 2500 actuators able to position the segment to nanometric precision. The delicate task of transporting the segments was assigned to Danish company DSV.

Having left France last week, the 18 polished mirror segments are now on their journey of over 10 000 km to the ELT’s construction site in the Atacama Desert. From there, ESO's ELT will tackle the biggest astronomical challenges of our time and make yet unimaginable discoveries once it starts operating later this decade.

More information

The European Southern Observatory (ESO) enables scientists worldwide to discover the secrets of the Universe for the benefit of all. We design, build and operate world-class observatories on the ground — which astronomers use to tackle exciting questions and spread the fascination of astronomy — and promote international collaboration for astronomy. Established as an intergovernmental organisation in 1962, today ESO is supported by 16 Member States (Austria, Belgium, Czechia, Denmark, France, Finland, Germany, Ireland, Italy, the Netherlands, Poland, Portugal, Spain, Sweden, Switzerland and the United Kingdom), along with the host state of Chile and with Australia as a Strategic Partner. ESO’s headquarters and its visitor centre and planetarium, the ESO Supernova, are located close to Munich in Germany, while the Chilean Atacama Desert, a marvellous place with unique conditions to observe the sky, hosts our telescopes. ESO operates three observing sites: La Silla, Paranal and Chajnantor. At Paranal, ESO operates the Very Large Telescope and its Very Large Telescope Interferometer, as well as survey telescopes such as VISTA. Also at Paranal ESO will host and operate the Cherenkov Telescope Array South, the world’s largest and most sensitive gamma-ray observatory. Together with international partners, ESO operates ALMA on Chajnantor, a facility that observes the skies in the millimetre and submillimetre range. At Cerro Armazones, near Paranal, we are building “the world’s biggest eye on the sky” — ESO’s Extremely Large Telescope. From our offices in Santiago, Chile we support our operations in the country and engage with Chilean partners and society.

Links

- Photos of the ELT

- Find out more about ESO's Extremely Large Telescope on our dedicated website and press kit

- For journalists: subscribe to receive our releases under embargo in your language

- For scientists: got a story? Pitch your research

Contacts

Marc Cayrel

Head of ELT Optomechanics at ESO

Garching bei München, Germany

Tel: +49 89 3200 6685

Email: mcayrel@eso.org

Bárbara Ferreira

ESO Media Manager

Garching bei München, Germany

Tel: +49 89 3200 6670

Email: press@eso.org

About the Release

| Release No.: | eso2319 |

| Name: | Extremely Large Telescope |

| Type: | Unspecified : Technology : Observatory : Telescope |

| Facility: | Extremely Large Telescope |