Protecting the Extremely Large Telescope from Earthquakes

ESO engineer Max Kraus tell us about newly-developed seismic technology

- The kinds of natural dangers faced by ESO telescopes

- How ESO engineers work to protect telescopes from earthquakes

- The brand new seismic technology being developed for the upcoming ELT

Q: Let’s begin with a basic question: what are earthquakes and why are they common in Chile?

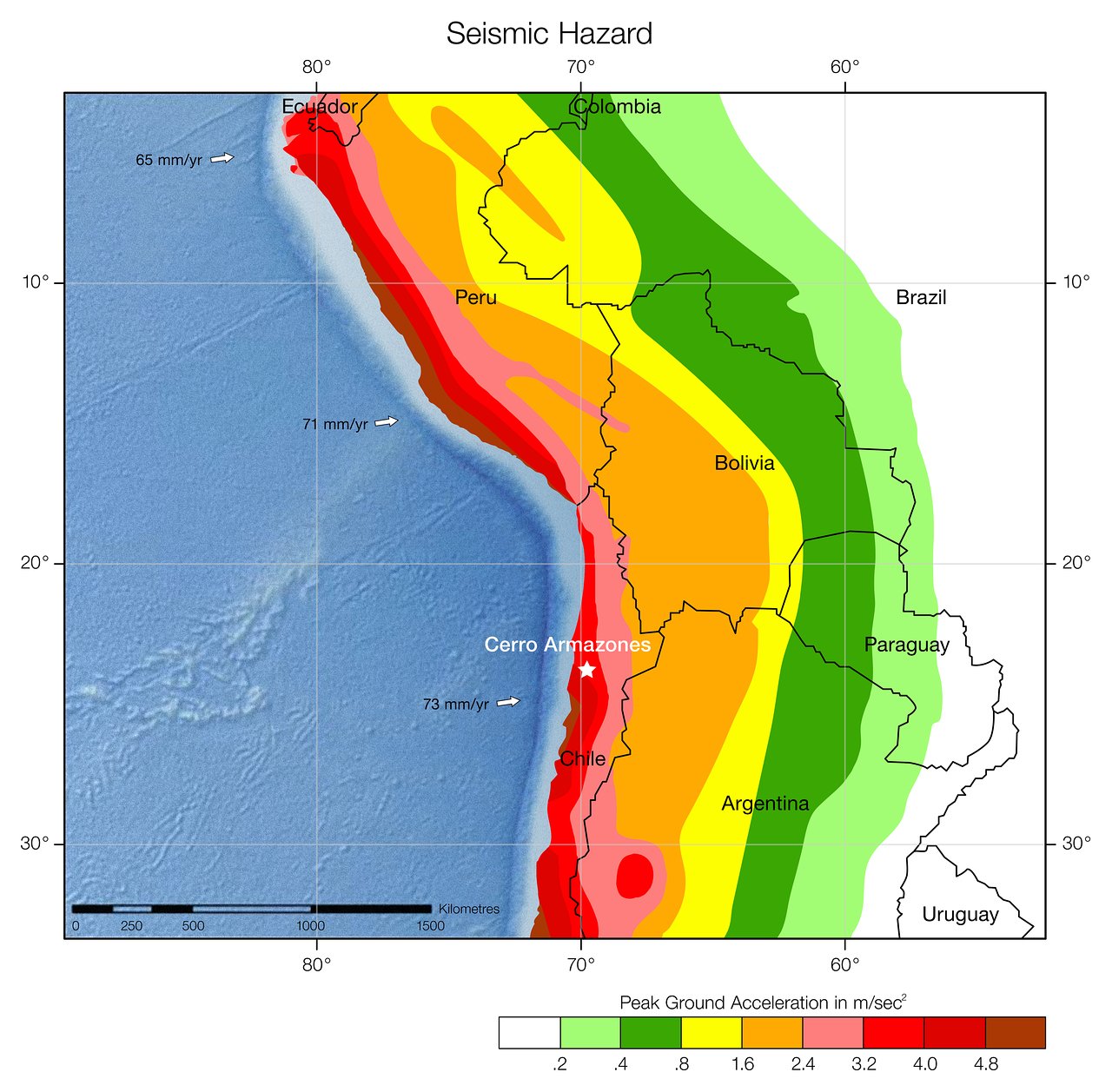

A: Earthquakes are sudden unpredictable movements of the ground due to the motions of Earth’s tectonic plates. They range in energy from tiny tremors to extremely large shocks, so strong that people can’t stand upright and even well-designed buildings are destroyed. Unfortunately, Chile is right at the intersection of two plates: the Nazca plate under the Pacific Ocean is being subducted under the South American continent. So earthquakes are common — Chile experiences on average two earthquakes above a magnitude of 1.5 every 24 hours, with a total of 677 in the past year.

Since ESO has decided to place its unique scientific facilities in this dangerous region due to its world-class night sky, adequate protection needs to be provided.

Q: Why is it so important to protect ESO’s telescopes from earthquakes?

A: Telescopes are composed of an intricate system of fragile components, fine-tuned to observe the Universe with incredible sensitivity and precision. Their optical mirrors and lenses are made from fragile glass ceramics such as Zerodur®, and any significant damage would take a telescope out of operation for a long time. Earthquakes, therefore, pose a great threat. Telescopes need to continue observing even after earthquake events with minimum loss of observing time and even inspections must be minimised, as time on these large science facilities is expensive.

As we build the Extremely Large Telescope (ELT), it is of utmost importance to consider the seismic risk in all design aspects of the telescope. One specific challenge is posed by the gaps between the 798 segments that make up the primary mirror. For observing reasons, these gaps must be as small as possible — but the mirrors must still be separated, as any contact between them during an earthquake would be devastating.

Q: Earthquakes are not a new problem in Chile. How has ESO dealt with them in the past?

A: ESO has previously designed efficient systems to help protect our telescopes from seismic activity. For example, ESO’s Very Large Telescope at the Paranal Observatory has a complex mechanical system that is automatically activated when it experiences a strong earthquake of magnitude 7 or higher. There are a series of clamps around the edges of the mirror, which can — at a moment's notice — lift the entire 23-tonne mirror off the actuators and secure it to the telescope’s support structure.

Interestingly, these mirrors are so expensive that they couldn’t be tested under real seismic conditions — so in the 1990s, ESO used the most advanced computer modelling and simulation tools of the time to investigate the effect of seismic shocks on delicate equipment. This allowed structures to be reinforced where necessary, or for dedicated protection systems similar to airbags to be installed. The metallic structures of the classical telescopes are also built on strong foundations that are anchored directly to solid rock, so the structure will move with the rock and not deform.

Over the past decades, Paranal has faced thousands of small seismic events and a few large earthquakes, including most recently in 2010 and 2014. Every time, the anti-seismic technology has risen to the challenge magnificently and protected the telescope.

Q: What different technology must be developed to protect the ELT?

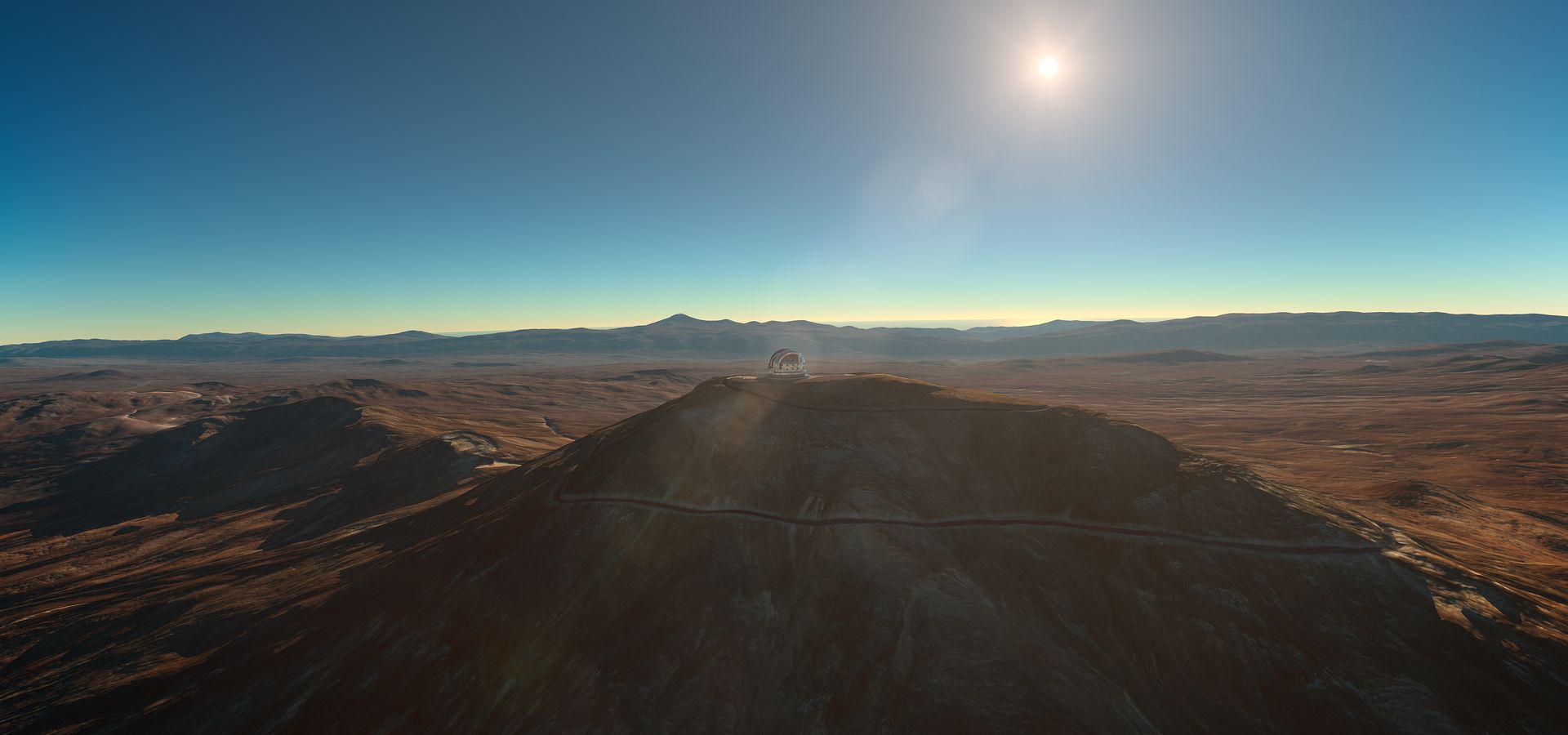

A: The sheer size and weight of the ELT telescope mean we can’t use the same strategy as the VLT. International specialists have been employed to study the seismic risks on the selected location of Cerro Armazones, and long-term measurements have been taken on-site to characterise the ground conditions.

For the past year and a half, we’ve been working with industry on ELT’s detailed design, and the seismic risks are assessed constantly. The anti-seismic concept of the ELT telescope and dome is based on seismic isolators, which are placed below the telescope between the base layer of the foundation and the rock. In case of an earthquake, the telescope and the dome foundation can slide horizontally on those isolators by as much as 30 centimetres to compensate for the ground movements, minimising shocks to the telescope. Our industry partners have already fully developed and tested this design.

But earthquakes don’t just act horizontally — seismic waves can also move vertically. Our simulations show that we will also need to prevent damage from vertical accelerations. We refer to this as “vertical damping”, and it’s more difficult to find existing industry hardware that meets the ELT telescope requirements — so we’ve had to develop new technology.

Q: Tell us about how you began the process.

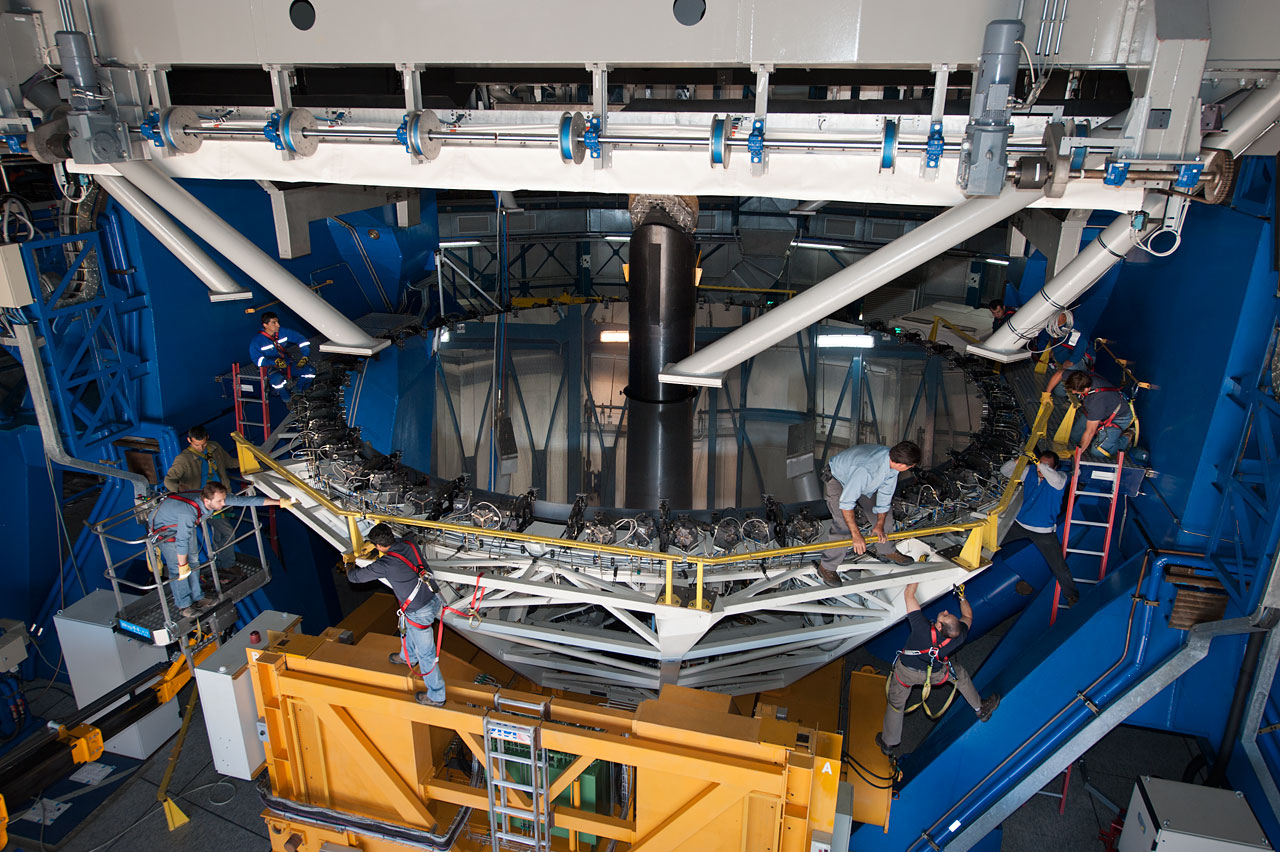

A: In parallel with our industry partner, we looked at similar problems we’d dealt with in other telescopes — for example in the Atacama Large Millimeter/submillimeter Array (ALMA), which is made up of 66 high-precision antennas that can be moved around into different configurations. When the 12-m antennas were transported over the unpaved roads at the observatory, they experienced potentially-damaging shocks. So ESO developed a vertical hydraulic damping (shock absorbing) system that was added to the ALMA antenna transporters and tested successfully.

Naturally, we studied this damping system to see if it could also be applied to the ELT. The goal of the system is to limit the forces transmitted from the road to the antenna by changing the oil volume in hydraulic cylinders that connect the wheels and transporter frame — essentially, the system absorbs the shock before it reaches the antenna. If configured correctly, it doesn’t need to be linked to an active sensing system. We realised that if we could also develop the ELT seismic damping technology without using an earthquake detection system located at large distance from the ELT site, it would simplify the process and avoid expenses and risks.

In the ALMA project, ESO also applied highly-sophisticated modelling and simulation tools to figure out how the system would behave in advance. Engineers could then optimise the components of the system. For the ELT, the same team of control specialists used similar modelling tools to predict how the mirrors will be affected by a seismic event — even incorporating profiles from earthquakes that have been developed as a design limit for the ELT construction.

Q: Tell us about the design concept you came up with as a result.

A: This gets a bit technical, but I’m sure the engineering-minded readers will appreciate it!

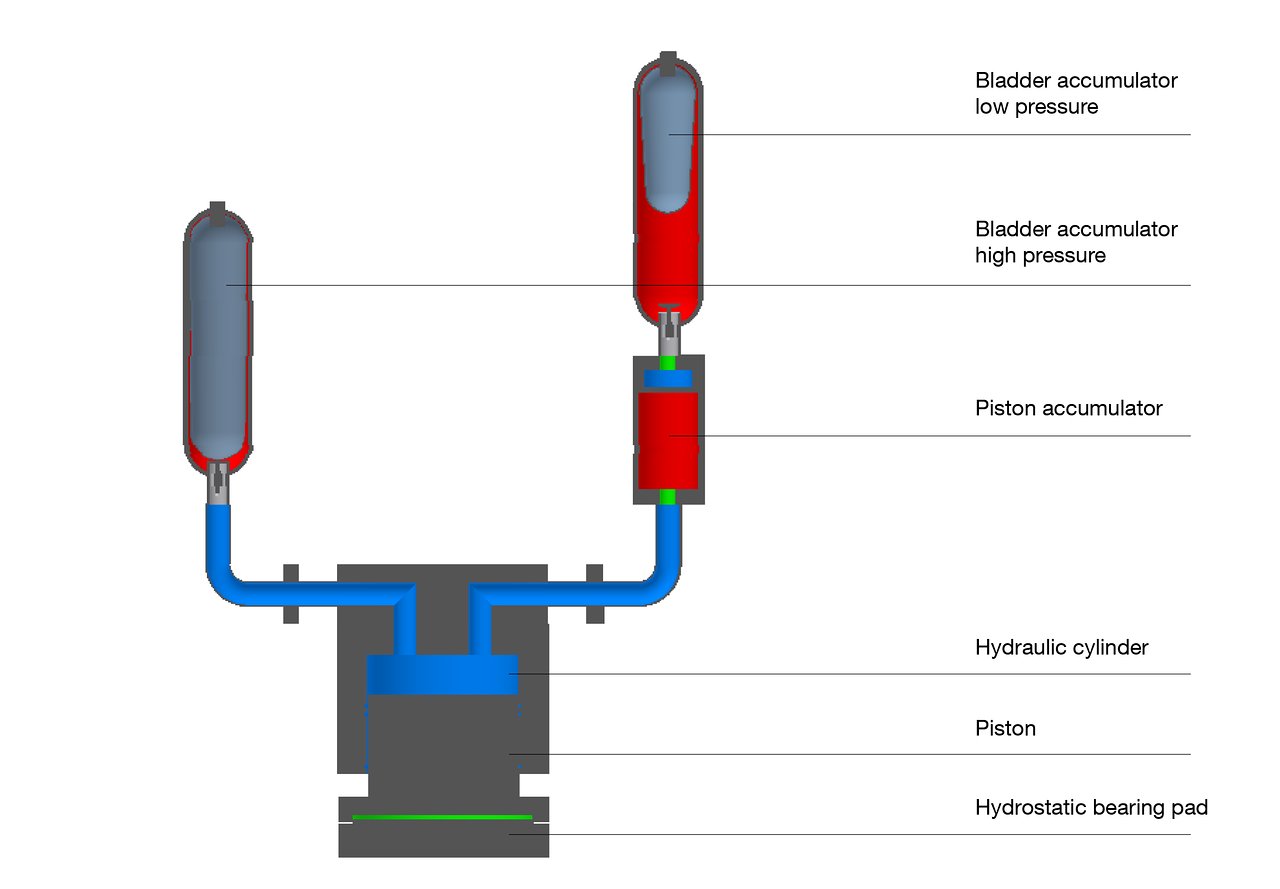

Firstly we had to figure out the best location in the ELT design for the vertical isolation dampers. This turned out to be the hydraulic pads of the telescope azimuth hydrostatic oil bearing — the telescope rotates on those pads on circular precision tracks with a thin oil film in between. These pads are kind of the equivalent to the hydraulic wheel supports for the ALMA transporter.

The main element of the damping system is a short (but wide) hydraulic piston, which provides the vertical motion required for the damping effect. The hydraulic piston is installed between the hydrostatic oil bearing pads and the telescope base frame. The cylinder oil volume is closed and the telescope weight rests on it and generates a constant pressure coming from the weight on each pad.

The damping effect is achieved by connecting a standard hydraulic bladder accumulator to the piston chamber. The accumulator is charged with a slightly higher pressure than the pressure generated by the telescope weight. During normal operation of the telescope, the accumulator is completely filled with pressurised gas and the oil remains in the piston carrying the telescope. A combination of damping and check valve is installed in the line between accumulator and piston to provide resistance and damping of the oil flow to the accumulator and allow a fast flow back to the piston.

In case of an earthquake, the upwards vertical acceleration from the ground increases the pressure in the cylinder until the oil flows into the accumulator — this happens automatically when the first large seismic wave reaches the telescope. As soon as oil flows into the accumulator, the telescope rests on the gas volume in the accumulator, which is a soft spring and absorbs the seismic shocks. In engineering language, the system’s natural frequency is hugely reduced and the lower system natural frequency protects the structure from dangerous accelerations.

After the acceleration event, the oil flows automatically back to the piston and the system is ready to continue operation.

Q: How different is this to the system used on the ALMA transporters?

A: The ALMA system successfully reduced the upward-directed shock from an earthquake. In case of our system for the ELT, we propose an extra accumulator combination in order to reduce the effect of the downward-directed shock wave that follows the upward-directed wave. Another accumulator charged with a slightly lower pressure as generated by the telescope weight is also connected to the same cylinder. In between this accumulator and the piston there is a piston accumulator. This piston accumulator acts as a valve: it blocks the flow to the accumulator in case of normal operation, and only in case of low cylinder pressure caused by the seismic event oil can flow to the second accumulator and again the telescope rests on a soft gas volume.

Q: Have you run simulations of this system?

A: Using the current telescope design of the ELT, we built a simulation model and equipped it with the proposed dampers. When we exposed the model to seismic events similar to those the ELT might experience, the simulation demonstrated that critical accelerations — for example, the damaging movement of the primary mirror — can be reduced significantly.

Q: What’s the next step for this system?

A: Right now, this design remains just a concept. If it’s pursued further, we’ll need to find an industrial partner with substantial hydraulic construction know-how and the capability to perform large-scale seismic testing. Together, we could develop a reliable technical product and verify the simulation results.

As a final comment, I’d like to acknowledge my co-authors on this project: B. Sedghi, M. Dimmler and M. Mueller. For the engineering-minded readers who would like to find out more, a more detailed technical explanation is in this paper.

Numbers in this article

|

2 |

Average number of earthquakes every 24 hours in Chile (M1.5 or greater) |

|

46–64 % |

Likelihood of earthquake with M8.7 or greater occurring in the next decade in Chile |

|

39.3 |

Diameter of the Extremely Large Telescope in metres |

| 798 | Number of the ELT primary mirror segments |

| 978 | Area of the ELT in m2 |

| 2024 | Planned first light date for the ELT |

Links

Biography Max Kraus

Max Kraus came to ESO as a mechanical engineer for the VLT project 28 years ago. Before joining ESO, he studied mechanical engineering at TUM in Munich and worked in aircraft design. Max enjoys working at ESO because of the large variety of technical challenges, as well as the new working cultures in international projects and the opportunity to put new systems into operation in the spectacular environment of Chile. He lives on a small farm and enjoys woodworking with hand tools.